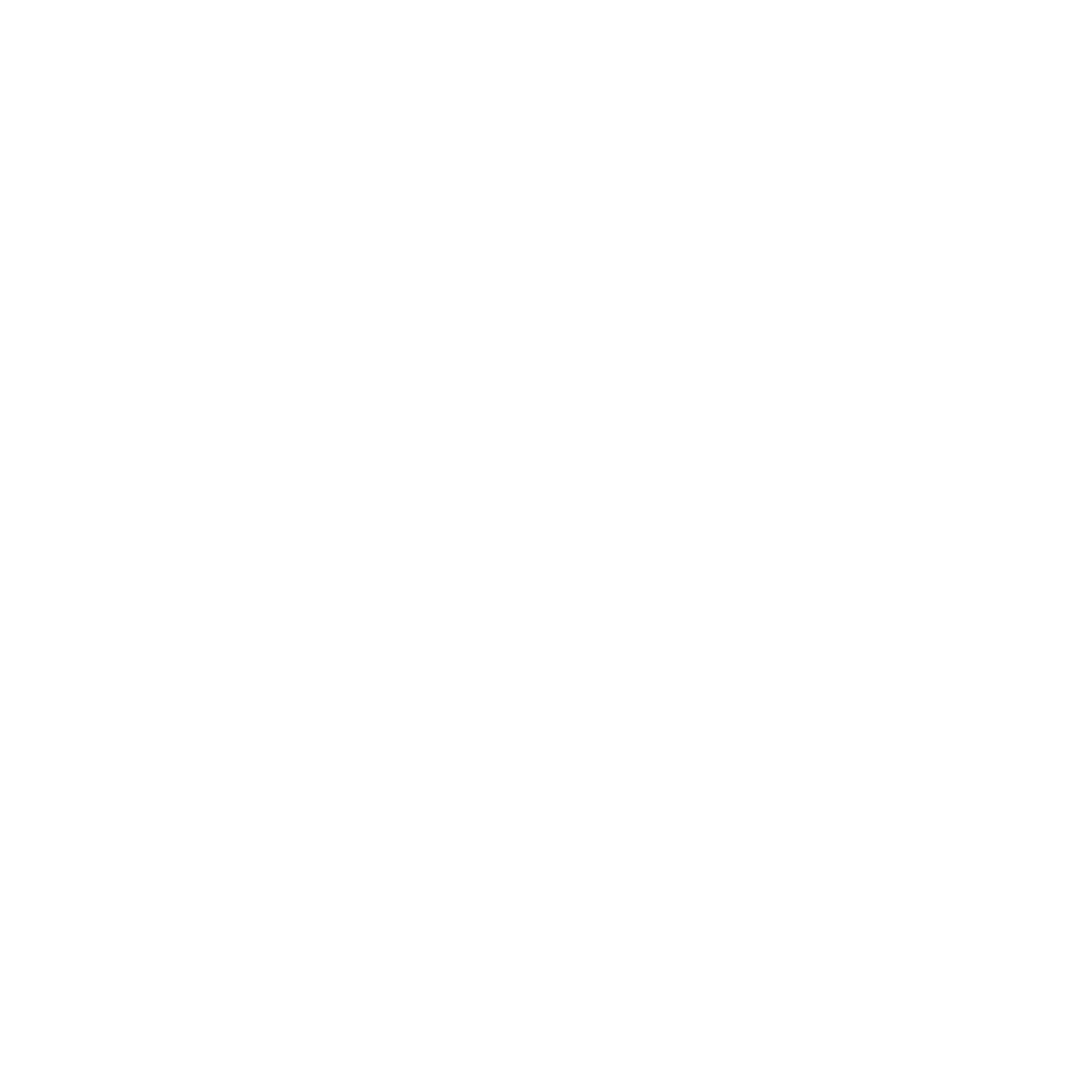

Spiro-Flex is a super light weight, flexible, compressible air duct. It consists of fibreglass reinforced aluminised PET foil tape, helically wound to encase a spring steel wire. Spiro-Flex conforms to any desired duct route, and its cross section is deformable.

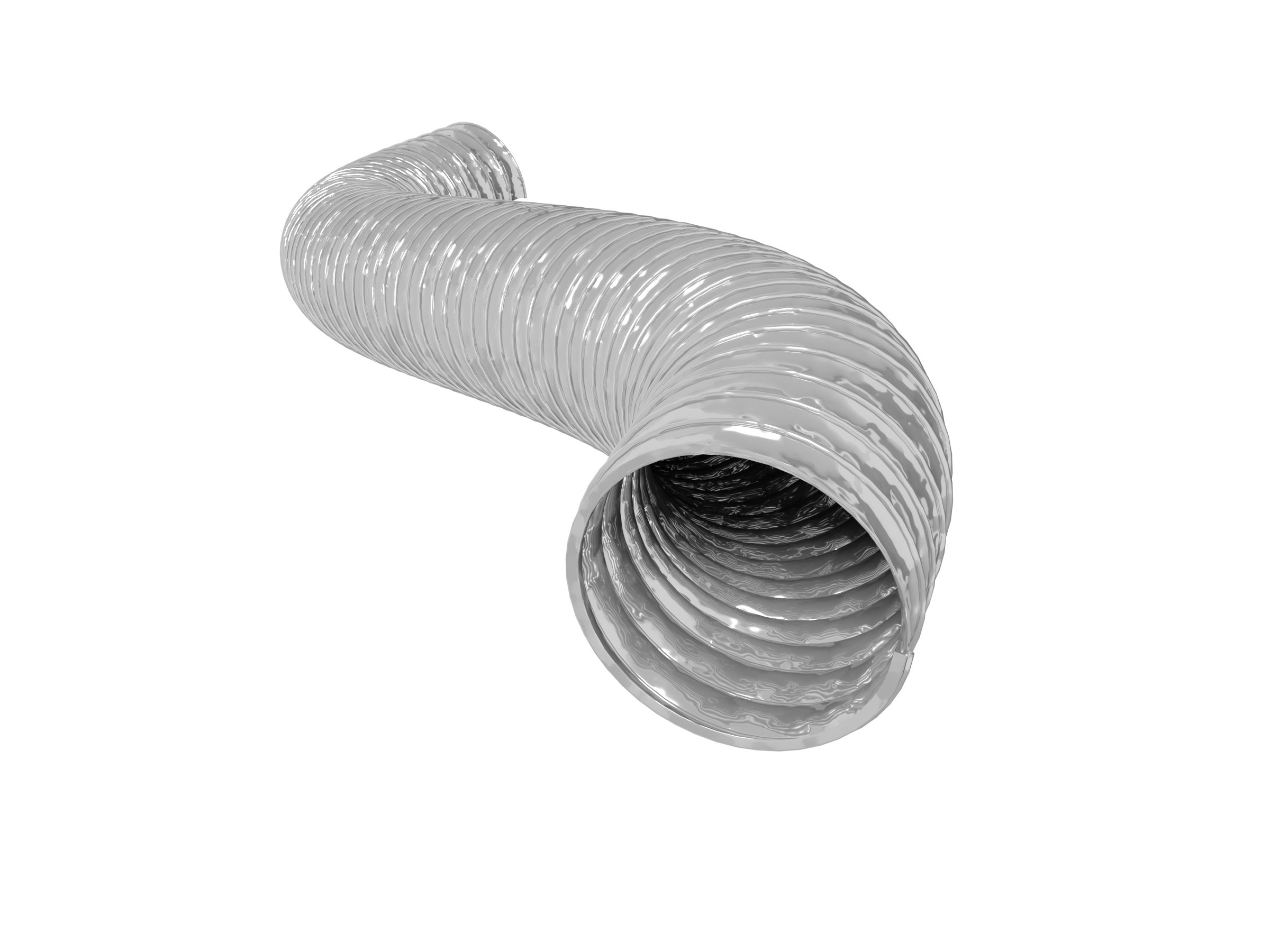

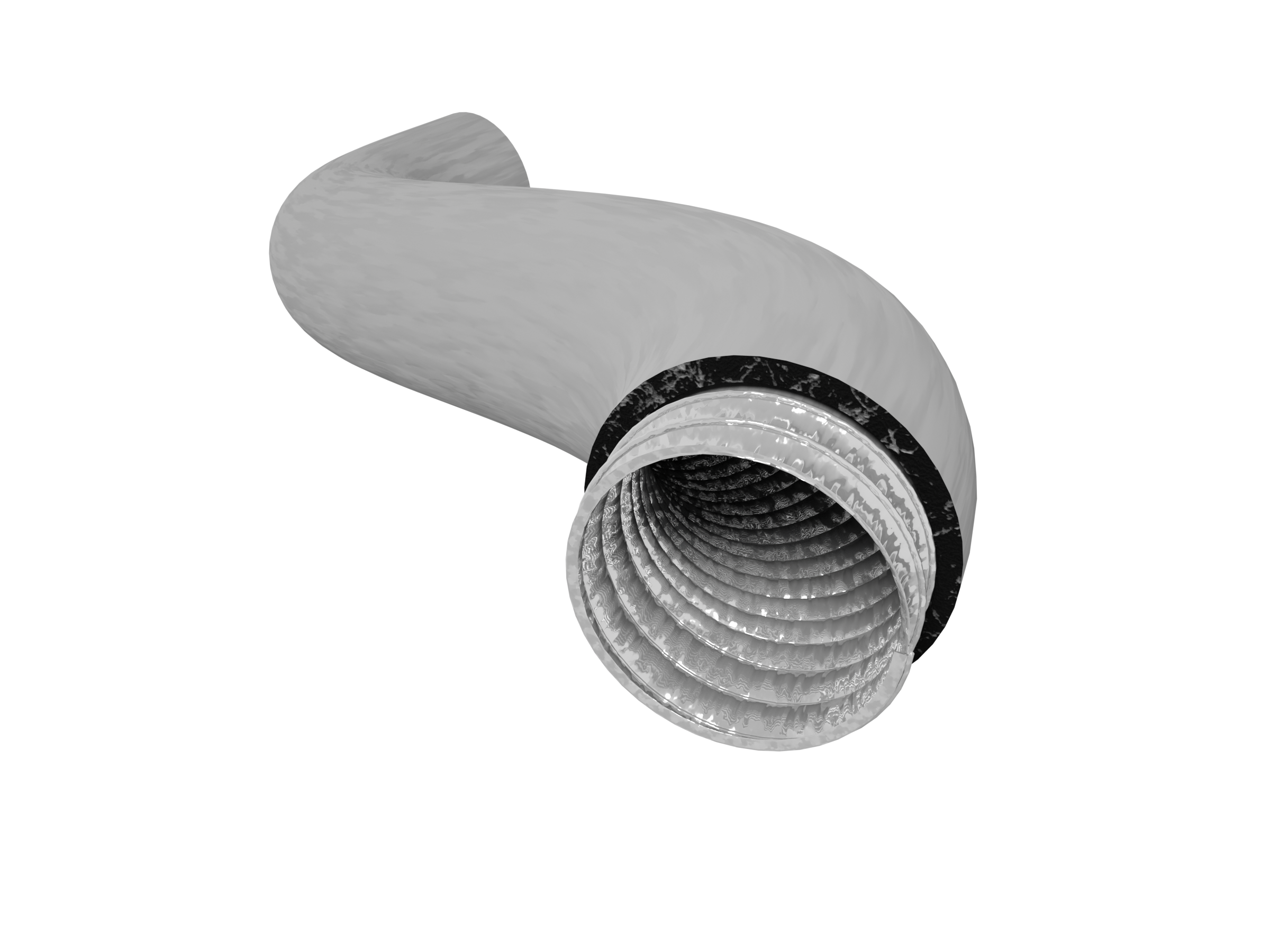

In the insulated form, Spiro-Flex is sheathed with a seamless, flame retardant printed outer sleeve.

SPIRO-FLEX

Flexible Duct

- Compliant with NZBC Energy Efficiency requirements from H1/VM3 Clause 5.2.1.

- Tested in accordance with AS 1530.3:

- Spiro-Flex Plain ducting received – Ignitability 0, spread of flame 0, heat evolved 0, and smoke developed 1.

- Spiro-Flex Insulated ducting received – Ignitability 0, spread of flame 0, heat evolved 0, and smoke developed 3.

- Tested in accordance with ISO 9705, receiving a 1-S Group Number Classification for smoke production rate in accordance with NZBC Verification Method C/VM2 Appendix A.

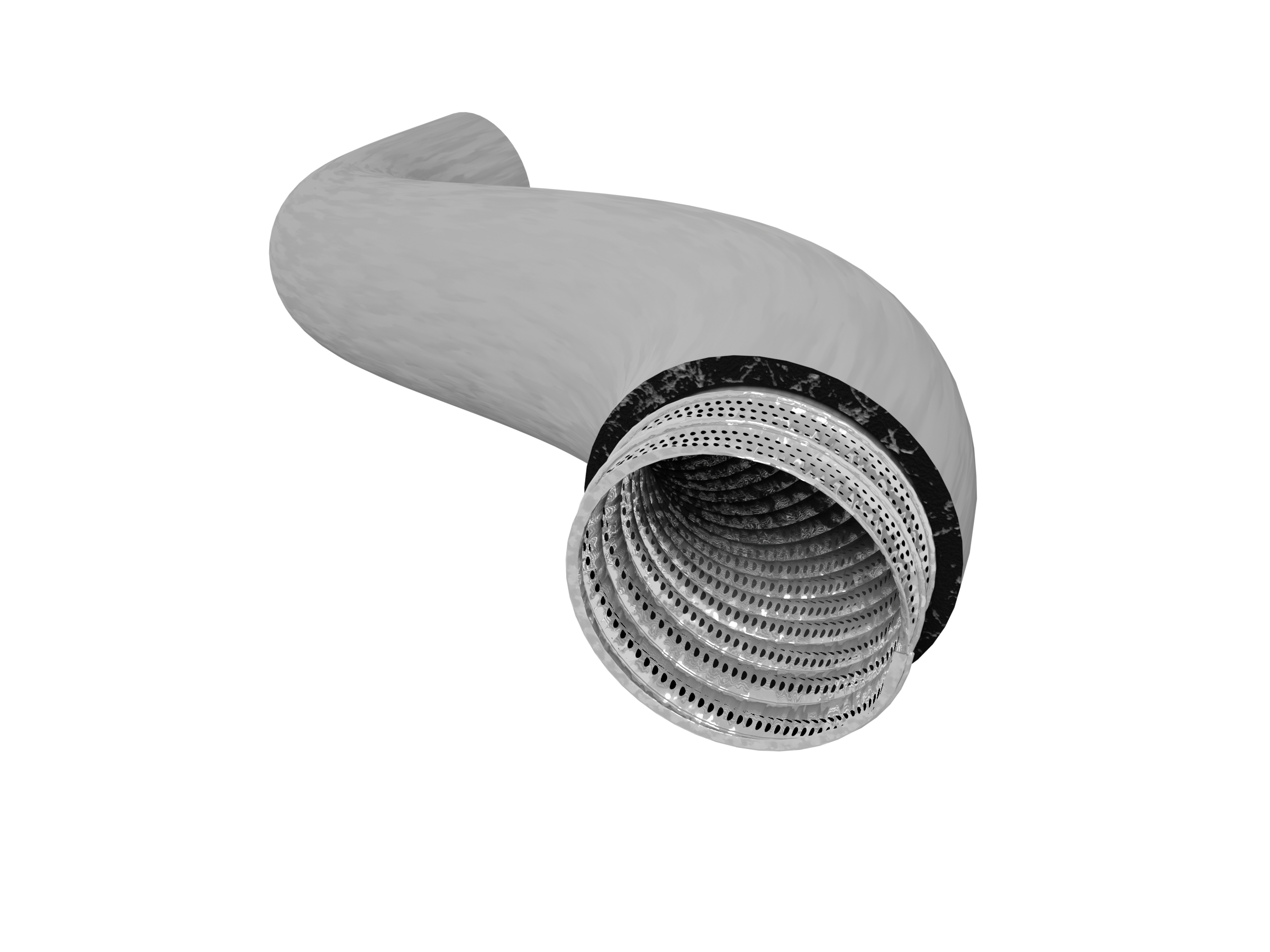

- Plain, insulated, or acoustic options available.

- Insulation is comprised of a lofted polyester blanket and a 100 micron polyethylene vapour barrier outer sleeve.